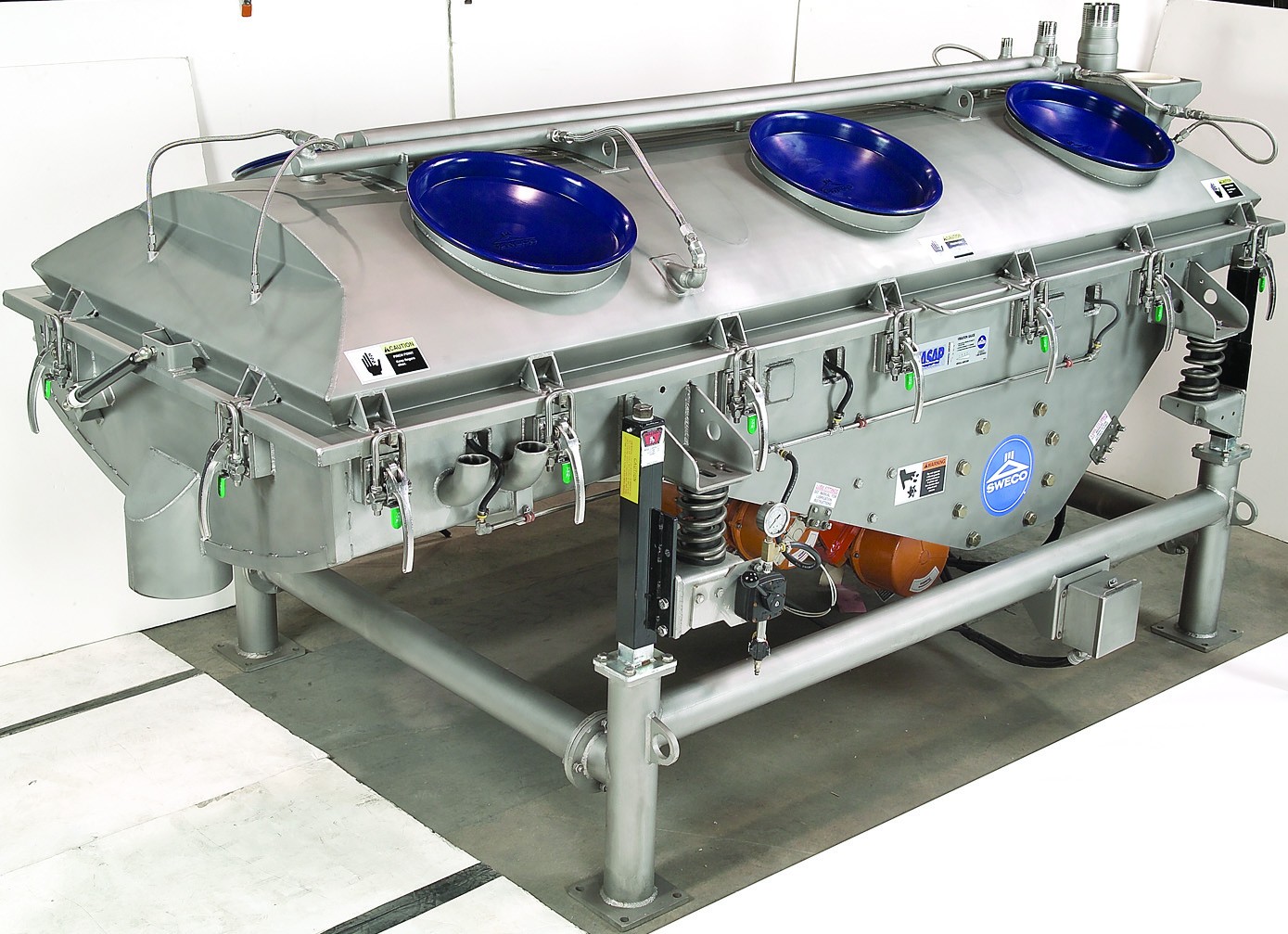

V3 Dual Motion Rectangular Separators

The V3 offers both elliptical and linear motion with just a flip of a switch. Both motions provide benefits, but primarily linear motion offers superior solids conveyance, and elliptical motion generates a much gentler motion and provides excellent screen life. Benefits of the V3 include few moving parts requiring little maintenance, easy screen changes, adjustable deck angle, clean and compact interior and a sanitary design.

Paper Coating CIP Rectangular Shaker

The SWECO Paper Coating Rectangular Shaker can filter "slurried coating ingredients", "blended virgin coatings", and "return coatings" containing fiber contaminants. With the ability to remove grit and fiber, the SWECO Paper Coating Separator reduces the chances of scratches and other defects in your coated papers. SWECO offers three sound options for a separation process in the Pulp & Paper Industry - the RM-CIP, UM-CIP and V3-CIP Rectangular Separators.

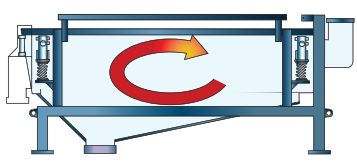

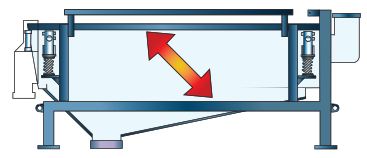

Elliptical or Linear Motion

The V3-CIP can be tailored to your process to produce either elliptical or linear motion. The high g-force produced by the patented drive allows for better conveyance and higher throughputs. The CIP features and modular design make the V3-CIP very easy to clean between production runs, and the machine can be polished to eliminate crevices where material tends to get trapped. The hinged cover makes changing screens easier than any other rectangular separator design.

SELF-CLEANING, HIGH CAPACITY RECTANGULAR

Sweco® now offers the latest in high capacity separation. The Sweco V3™ Rectangular Separator offers both elliptical motion and linear motion with just a flip of a switch. So depending on the specific application, users are afforded the luxury of choosing the motion that will best fit their process. Linear motion offers superior solids conveyance, ideal when large volumes of solids are processed. Elliptical motion utilizes engineered uni-directional motion combining a strong conveying action with a consistent adjustable ellipse down the full length of the screen deck to provide quick conveyance and excellent screen life.

Sweco® now offers the latest in high capacity separation. The Sweco V3™ Rectangular Separator offers both elliptical motion and linear motion with just a flip of a switch. So depending on the specific application, users are afforded the luxury of choosing the motion that will best fit their process. Linear motion offers superior solids conveyance, ideal when large volumes of solids are processed. Elliptical motion utilizes engineered uni-directional motion combining a strong conveying action with a consistent adjustable ellipse down the full length of the screen deck to provide quick conveyance and excellent screen life.

The V3 has very few moving parts that will require little if any maintenance. The interior surfaces have fewer cross-members that make the V3 easier to polish for sanitary applications that require a crevice-free surface. Additionally, the screen basket can be polished to a mirror finish. V3 pretentioned screens are quick and easy to change. After unclamping and lifting the hinged top cover, any screen can simply be lifted out of the machine regardless of its location.

For fine mesh applicatins where an absolute minimum of oversized material is allowed, the screens are 100% sealed by patented pneumatic seals for zero bypass. The unit’s patented drive produces up to 5.5 G’s for extra conveyance, and a clean-in-place option is available.

Its dual motion, high capacity, sanitary design makes the V3 ideal for use in such industries as kaolin clay, food, paper coating, and ceramic slip to name just a few. This unique rectangular separator is one of the most advanced in the industry, as Sweco ushers in a new era for high-volume processing.

Fast and Simple Screen Changes

The V3 Rectangular Separator has many advantages adding to its flexibility and versitility as a high-volume screener. The V3’s deck angle can be inclined or declined at a range of 5° to maximize the effectiveness of the system. Furthermore, all accessories available with other rectangular separators are accessible with the V3, including self-cleaning screens, vibrating spray systems, spray balls, misting nozzels, acid washdown, and vibrating covers.

The V3 Rectangular Separator has many advantages adding to its flexibility and versitility as a high-volume screener. The V3’s deck angle can be inclined or declined at a range of 5° to maximize the effectiveness of the system. Furthermore, all accessories available with other rectangular separators are accessible with the V3, including self-cleaning screens, vibrating spray systems, spray balls, misting nozzels, acid washdown, and vibrating covers.

Benefits of the Sweco V3 Rectangular Separator

» Quick and easy screen changes and maintenance

» Zero bypass of material

» Clean and compact interior

» Simple clean-in-place system

» Dual motion

» Adjustable deck angle (range of 5°)

» Minimal maintenance required

» Sanitary design

» High G-force

Any mineral slurry with relatively large percentage of oversize, such as calcium carbonate, kaolin clay, and lime slaking

Any mineral slurry with relatively large percentage of oversize, such as calcium carbonate, kaolin clay, and lime slaking Wastewater reclamation, dewatering coal, calcium hydroxide, and effluent clean-up.

Wastewater reclamation, dewatering coal, calcium hydroxide, and effluent clean-up.